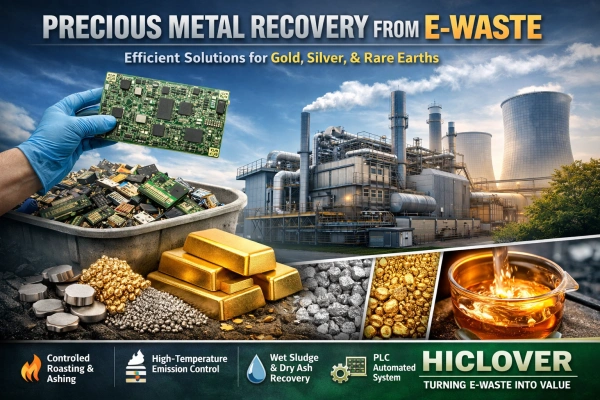

Precious Metal Recovery from E-Waste: Industrial Trends and the Role of HICLOVER Thermal Systems

1. Industry Background: Why E-Waste and Precious Metals Matter Now

Global demand for gold, silver, platinum-group metals, and rare earth elements continues to accelerate, driven by electronics manufacturing, renewable energy systems, electric vehicles, AI data centers, and defense industries. At the same time, primary mining faces increasing constraints: declining ore grades, environmental pressure, geopolitical concentration of resources, and long permitting cycles.

As a result, electronic waste (e-waste) has become a strategic secondary resource. Printed circuit boards (PCBs), connectors, relays, chips, sensors, and coated components often contain metal concentrations far higher than natural ores. Urban mining and controlled recycling are now recognized as critical pillars of supply security.

However, efficient recovery depends on proper pre-treatment. Organic binders, plastics, resins, oils, and coatings must be removed safely and cleanly before downstream hydrometallurgical or pyrometallurgical refining. This is where controlled thermal technology becomes decisive.

2. Challenges in Conventional E-Waste Processing

Many recyclers struggle with:

-

Incomplete removal of organics, causing low recovery rates

-

Excessive smoke, odor, and VOC emissions

-

Fouling of downstream furnaces, filters, or leaching systems

-

Loss of precious metals in uncontrolled ash or fly dust

-

High labor intensity and unstable batch quality

Open burning or uncontrolled incineration not only violates environmental regulations but also destroys value by dispersing recoverable metals.

3. The HICLOVER Approach: Controlled Thermal Pre-Treatment

The HICLOVER Precious Metal Recovery Furnace is engineered specifically for e-waste and precious-metal-bearing materials, acting as a thermal preparation step before final metal extraction.

Rather than “burning waste,” the system focuses on controlled roasting and ashing, maximizing metal retention while stabilizing emissions.

Typical Feed Materials

-

Electronic scrap intermediates

-

Precious-metal-loaded resins and activated carbon

-

Plastic-coated connectors and cables

-

Oily residues and coated components

-

Laboratory or pilot-scale recycling residues

4. A/B/C Process Logic for Maximum Recovery

Stage A C Controlled Low-Temperature Roasting / Ashing

Organic materials are gradually removed under carefully managed temperatures. Plastics, resins, and oils are volatilized without violent combustion.

-

Produces dry, metal-rich ash

-

Ash is collected via movable high-temperature trays

-

Enables centralized handling and accurate mass balance

-

Minimizes metal oxidation or dispersion

This stage is critical for protecting gold, silver, palladium, and platinum content.

Stage B C High-Temperature Afterburner

All oil smoke, VOCs, and pyrolysis gases released in Stage A are fully oxidized.

-

Eliminates black smoke and odor

-

Prevents tar fouling and sticky deposits

-

Stabilizes downstream gas treatment systems

-

Improves overall plant cleanliness and uptime

Optional Stage C C Quench Spray Scrubber

For higher environmental control or oil-rich feedstocks:

-

Rapid gas quenching and washing

-

Acid gas and particulate capture

-

Demisting before stack discharge

-

Generates wet sludge, which can be periodically removed and re-ashed to recover residual metals

This closed-loop logic ensures no recoverable value is wasted.

5. Key Technical Advantages for Recyclers

-

Dry ash + wet sludge centralized recovery for maximum precious metal retention

-

Stable, clean operation with reduced maintenance

-

PLC recipe control: temperature curves, residence time, airflow, interlocks

-

Customizable chamber volume and throughput capacity

-

Fuel options: Diesel / Natural Gas / LPG

-

Modular structure, with containerized or mobile configurations for fast deployment

For recyclers scaling from pilot lines to industrial operations, this modularity reduces capital risk while maintaining process consistency.

6. Alignment with Global Hot Topics: Rare Earths and Strategic Metals

Beyond gold and silver, modern electronics contain rare earth elements and specialty metals essential to permanent magnets, sensors, and energy storage systems. Governments and industrial groups increasingly promote domestic recycling capacity to reduce reliance on volatile mining regions.

Thermal pre-treatment systems like the HICLOVER solution support this shift by:

-

Enabling cleaner separation before chemical refining

-

Improving compliance with tightening emission standards

-

Supporting circular-economy and ESG objectives

-

Allowing deployment near urban collection centers or industrial parks

7. Typical Application Scenarios

-

E-waste recycling plants (PCBs, connectors, mixed electronics)

-

Precious metal recovery workshops and refineries

-

Battery and electronics R&D laboratories

-

Industrial waste treatment centers handling metal-bearing residues

-

Emerging markets developing localized recycling infrastructure

8. Conclusion: Turning Waste into Strategic Resources

As precious metals and rare earths become increasingly strategic, efficient and controlled thermal pre-treatment is no longer optional―it is foundational. The HICLOVER Precious Metal Recovery Furnace provides recyclers with a clean, controllable, and value-preserving pathway from complex e-waste to recoverable ash.

By combining low-temperature roasting, high-temperature afterburning, and optional wet scrubbing under PLC control, HICLOVER enables recyclers to protect both environmental compliance and metal yield, transforming electronic waste into a reliable secondary resource stream.

For manufacturers, recyclers, and institutions seeking scalable and responsible solutions, HICLOVER thermal systems represent a practical bridge between today’s waste challenge and tomorrow’s resource security.

Comments are closed